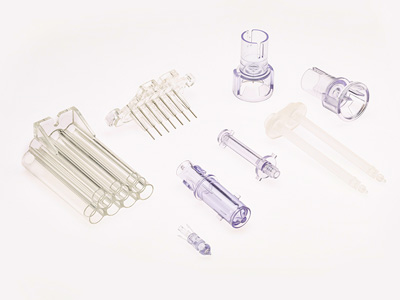

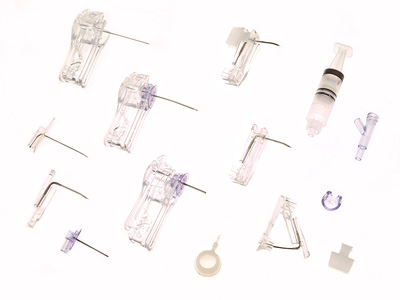

Precision Miniature Molding

With decades of experience in miniature medical molding, Intricon routinely achieves tolerances of ±.0005 inches in compliance with ASTM and SPI standards while utilizing Scientific Injection Molding (SIM) practices. As a joint development manufacturer, we can support you every step of the way, from engineering, design, and prototyping to high volume production. We work with a broad range of materials such as polyether ether ketone (PEEK), nylon (PA), polypropylene (PP), liquid crystal polymer (LCP), acrylic (PMMA), polyoxymethylene (POM), polycarbonate (PC) and more.

Reel-to-reel molding techniques enhance the quality and cost-effectiveness of many insert- and injection-molded solutions, greatly reducing human error and providing labor savings by eliminating the need for handling. Reel-to-reel also facilitates feeding parts directly into our automation systems. Once the reel-to-reel molding process concludes, the product then can undergo a full range of secondary manufacturing operations such as welding, wire bonding, soldering, part numbering and/or singulation.